cutting & engraving machine

English

As a professional digital tool, CO2 laser cutting machines have efficient processing capabilities. Meanwhile, laser processing safety issues must cannot be ignored at all times. If the machine is used improperly, it will cause serious damage to our human body including eyes and skin, and even cause fires, electric shocks and burns to children.

In order to avoid unnecessary injury and normal use of laser machines, we have summarized and sorted out the precautions and processes on the safe use, cleaning and maintenance, and operation process recommendations of CO2 laser cutting and engraving machines for your reference.

CO2 laser machine safety protection

Laser processing sites should be equipped with effective ventilation devices and fire extinguishers that suitable for different processi ng materials. For example, foam fire extinguishers are suitable for use in fires caused by the burning of solid combustibles such as wood and rubber.

2. During the working process of the machine, the operator must observe the processing situation to prevent accidents. In particular, when many people are watching, the operator should pay attention to the surrounding environment and avoid injuring others when opening the machine door or moving the laser head.

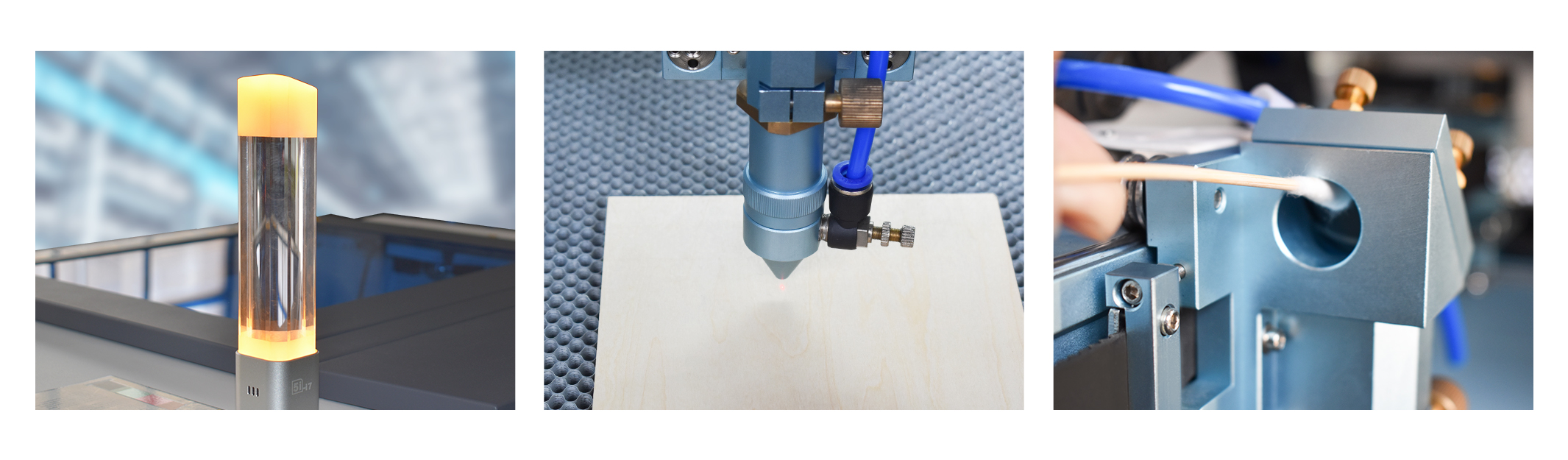

3. During the operation of the laser cutting machine, the air pump or air compressor must be turned on to maintain the air blowing state to avoid material burning. If there a large amount of smoke or material burning during processing inside the machine, you need immediately press the emergency stop switch to stop processing, and use a fire extinguisher to put out the fire if necessary.

4. Although the CO2 laser cutting machines can process a variety of materials, but, please note that not all materials are suitable for laser cutting or engraving processing. If you need to processing other unknown materials with the laser machine, please check or consult a laser professional first, in case of any hazards caused by unsuitable materials for processing on such strong laser power cutting machine.

5. Do not place any flammable materials inside the laser machine. And always remember to clean up the waste generated after processing in time to prevent it from being ignited by the laser source and causing a fire.

6. After completing the laser cutting or laser engraving processing work with the machine, the operator must turn off all switches and power sources of the machine, and remove the machine switch key in time to prevent other unprofessional personnel from accidentally opening and using it.

Laser processing maintenance items & steps

Maintenance items | Operating steps | Maintenance tool | Maintenance period |

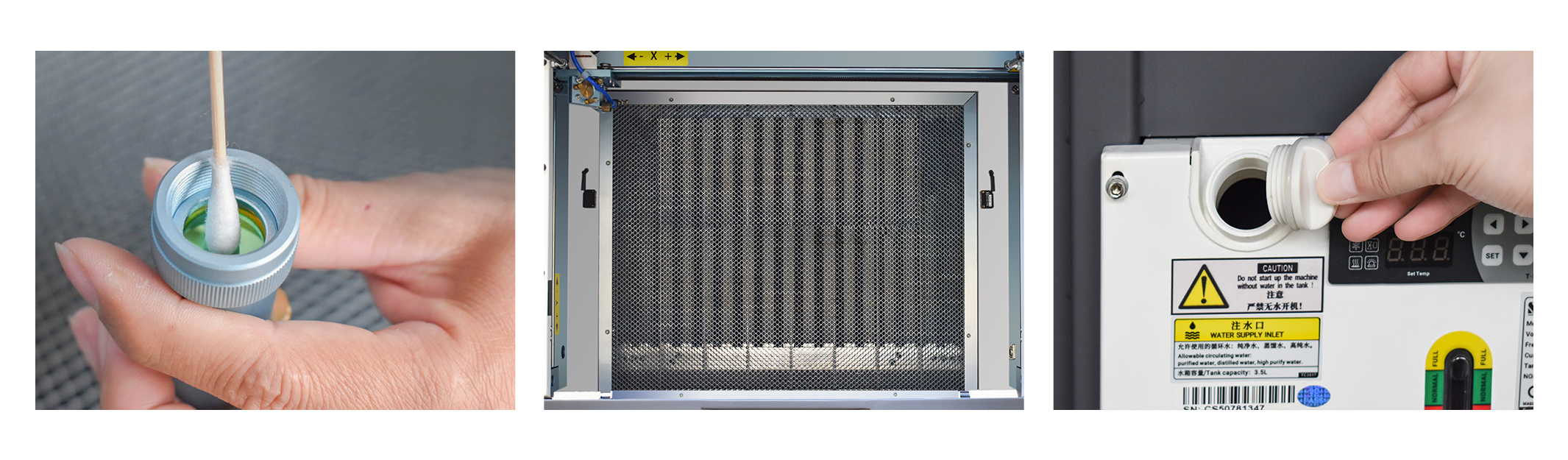

Laser focus lens | 1. Remove the laser head 2. Take out the focusing lens 3. Clean the focusing lens 4. Install focusing lenses 5. Install the laser head | Glass cleaning cloth Lens cleaner or alcohol | After daily use |

The reflector lens | 1. Clean the first reflector lens located at the laser tube 2. Clean the second reflector lens located to the left of the X axis 3. Clean the third reflection lens located above the laser head | Glass cleaning cloth Lens cleaner or alcohol | |

Waste collection tank | 1. Open the scrap hatch 2. Clean up material debris and other waste materials 3. Close the waste compartment door | Vacuum cleaner or other cleaning tool | Once a week |

The machine surface | 1. Clean the machine processing window and surface 2. Remove dust from inside the machine 3. Remove the honeycomb board waste and dust 4. Clean the laser tube surface | Window cleaner Clean cloth | Once a week |

Motion rail and pole | 1. Add lubricating oil to the guide rails of X and Y axes 2. Add lubricating oil to the lead screw of Z axis | Lubricating oil brush | Once every two weeks |

Combiner mirror Air extraction channel | 1. Clean both sides of the lens | Glass cleaning cloth Lens cleaner or alcohol | |

1. Clean the exhaust baffle at the back of the waste bin 2. Clean the inlet of the exhaust fan 3. Check whether the exhaust pipe is blocked | Vacuum cleaner or other cleaning tool | ||

Water tank | 1. Clean the machine processing window and surface 2. Remove dust from inside the machine Replacement of cooling water 3. Remove the honeycomb board waste and dust 4. Clean the laser tube surface | Purified or distilled water | Once a month |

Filtrating screen | 1. Loosen the screws on the air inlet and air outlet Clean filter 2. Remove the air filter for cleaning |

Laser processing use steps

1 Open the water tank | • Ensure the water level of the tank is kept within normal range |

2 Turn on the laser cutting machine | • Turn the protection key to "On" • Turn on the main power supply • Power on the laser |

3 Transfer the design to the laser cutting machine | •Check whether the computer equipment is successfully connected to the laser cutting machine • Check that the parameters of the design drawing are set correctly |

4 Place the material on the laser processing platform | • Ensure smooth processing materials • Ensure that the focal length is correct |

5 Close the laser cutting machine door | • Pay attention to the surrounding environment when closing to avoid injuring others |

6 Set the processing starting point and confirm the processing range | • Ensure that the processing scope is within the material |

7 Start processing | • During the machine processing, there must be personnel to observe the processing situation whole time, to ensure the normal operation of the machine and processing safety • In case of an emergency, press the "Emergency Stop" button immediately |

8 Open the door of the laser cutting machine and take out the parts | • Check that the material is completely cut through • Check the integrity of the parts in case they are lost |

9 Turn off the laser cutter machine | • Power off the laser • Turn off the main power supply • Rotate the protection key to "Off" and remove the protection key |

10 Turn off the water tank | • Make sure that the device is powered off |

For more information or questions about our Good-Laser Light series CO2 laser cutting machine’s safety usage, maintenance and operation, please feel free to contact our technical service at support@good-laser.com.